Brothers restore and manufacture nomadic structures to include modern updates, giving public a peek into history, Yang Feiyue reports.

Whenever Ban Fengbin has time, he visits a yurt he purchased from a local herdsman's family several years ago.

"They barely used it," says the man born and raised in Sonid Right Banner, Xiliin Gol League in the Inner Mongolia autonomous region.

With more than three decades of yurt-building experience, Ban estimates that this yurt has stood the test of time for over a century and housed at least three generations of herders.

"Although this yurt doesn't conform to modern standards, it serves as a great historical piece that allows us a peek into the past lifestyles of our predecessors," he says.

Due to its long history and poor preservation, the yurt has suffered various damage.

Over the years, Ban and his team have restored it bit by bit according to the traditional yurt construction principles.

"The wool felt has become so brittle that we don't use too much force to restore it," Ban says.

He brought the yurt to public attention during the 34th Naadam festival in Xiliin Gol League in July. It instantly stood out among hundreds of its counterparts and attracted many visitors.

In his opinion, the yurt possesses the essence of nomadic culture, which highlights the convenience of life.

"For yurt construction, it boils down to six words — easy to disassemble, easy to reassemble. This has been our principle all along," Ban explains.

Also known as a ger in Mongolian, yurts have been a traditional, portable round tent used as a dwelling by the nomadic people in the region.

Its development is deeply intertwined with nomadic lifestyles and the need for a mobile yet sturdy and comfortable shelter in the harsh and variable steppe climate.

In the Western Han Dynasty (206 BC-AD 24), writer Huan Kuan described the yurt in Discussions on Salt and Iron (Yantie Lun) as woven willow forming the structure, with felt used to cover the roof.

During the Yuan Dynasty (1271-1368), Mongols elevated yurt-making to unprecedented heights, as recounted by Southern Song Dynasty (1127-1279) official Peng Daya in a document.

Recounting Peng's experiences during a visit to the Mongols, the work depicted two types of yurts. One was foldable and used willow as the frame. It was covered with felt and had a door at the front and a top resembling umbrella ribs, as well as an open vent.

The other type featured willow woven into rigid hoops secured by felt, and cannot be folded. It was normally loaded onto carts and moved when a pasture was exhausted.

As Mongol tribes pledged allegiance to the rising Qing Dynasty (1644-1911), Qing emperors often held formal ceremonies and banquets inside enormous yurts to make the visiting tribal leaders feel welcome.

"Early yurts for civilians were simple, made from wood and animal hides, with a structure of wooden poles that could easily be dismantled and reassembled. The circular shape provided strength and resistance against high winds," Ban says.

READ MORE: All the world's a stage

Witnessing his grandfather and father building yurts for local herdsmen, Ban followed in their footsteps out of "a sense of belonging and responsibility".

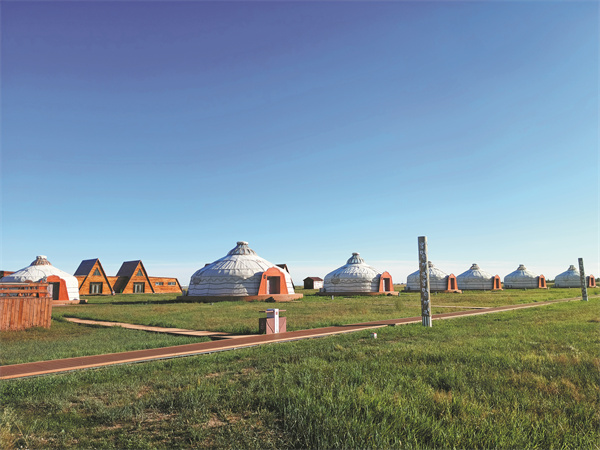

The construction technique of the yurt involves drawing a circle on the ground. Based on the size of the circle, several wooden strips are woven into a lattice structure to form the walls. Once the walls are built, the umbrella-shaped roof is connected to the wooden lattice. The framework is then covered with felt and tied down with rope.

"The top of the yurt has a skylight for ventilation and lighting, which can be covered during rain," Ban says.

In 2008, the craftsmanship was listed as a national intangible cultural heritage.

Additionally, yurt construction techniques integrate woodworking, embroidery, carving, painting and weaving.

"The patterns are mostly of clouds, grass and animals for decoration," Ban says.

ALSO READ: Mongolian yurts making a comeback

Wood, rope and felt are chosen because they are readily available on the grasslands and render the yurts lightweight, portable and reusable, which makes for convenient construction, dismantling, relocation and repairs, Ban explains.

In 2012, his younger brother Ban Fenggong quit his job at a local State-owned company and joined his cause in establishing a yurt production facility.

It was a decision from Ban Fengbin's influence and the market potential.

"Even though residents now live in concrete houses as their living standards improve, some still need a yurt placed next to their house to receive guests or they buy it as a wedding gift," Ban Fenggong notes.

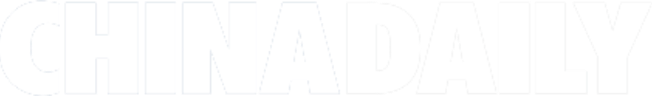

"Additionally, with the rise of the culture and tourism industries, many guest-houses in Inner Mongolia and Mongolian restaurants in other places, including Shanghai and Hong Kong, are our clients," he adds.

The two brothers have also continued to innovate based on traditions to better meet market demand. They incorporate mechanical equipment to improve production efficiency and have developed a blend of wool and synthetic fibers to address the problems of wool attracting insects and sending out an unpleasant odor.

To enrich yurt decorative art, they incorporate computer engraving, painting and metal.

To date, they have expanded the types of yurts from a dozen styles to over 150. They produce 100-200 yurts for customers nationwide each year.

The rising business has also created more job opportunities for local herdsmen.

They have hired more than 20, each spending a few months working on yurts when they aren't working on farming.

Each earns 30,000 ($4,224) to 50,000 yuan a year from the business, according to the Ban brothers.

Although he joined the yurt business later, Ban Fenggong has become an expert in the trade.

"There are many details to consider when constructing a yurt. For example, the stove is made of clay and plant fibers for better heating and its walls are hollow so the sparks from burning cow dung can be precipitated and thus less likely to spill onto the grasslands outside," he explains.

In addition to yurt production, the brothers developed miniature yurt-making kits that enable students to appreciate the construction.

About 200-400 primary and middle school students will receive such training each year, according to them.

In March, their facility was named a national model site for production-based intangible cultural heritage protection by the Ministry of Culture and Tourism.

The Ban brothers say the title has given them a stronger incentive to continue the yurt culture.

"We are working on an intangible cultural heritage exhibition and have collected more than 100 old yurts, carpentry and daily tools from local herdsmen," Ban Fengbin says.

"Hopefully, more people will understand our culture better through yurts," he adds.